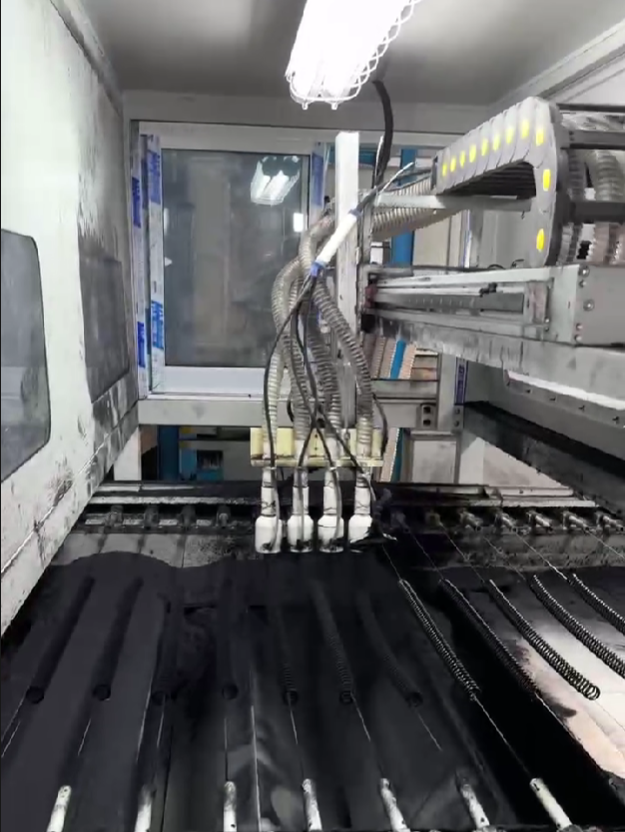

汽车尾门弹簧植绒流水线是专为汽车尾门弹簧设计的自动化植绒设备系统,核心用于在弹簧表面形成均匀绒毛层,减少弹簧工作时的异响与磨损。流水线主要包含弹簧上料、表面清洁、涂胶、植绒、烘干固化及下料环节,全程自动化运行:弹簧经上料系统输送至清洁工位去除油污,随后涂胶工位均匀涂覆专用粘合剂,再进入植绒区通过静电吸附使绒毛附着,最后经烘干工位(温度 80-120℃)固化粘合剂,完成植绒。设备适配不同规格尾门弹簧,植绒均匀度高,能提升弹簧静音性与使用寿命,广泛应用于汽车尾门弹簧批量生产。

The Automotive Tailgate Spring Flocking Production Line is an automated flocking equipment system specially designed for automotive tailgate springs. Its core function is to form a uniform flocking layer on the spring surface to reduce abnormal noise and wear during spring operation. The production line mainly includes spring feeding, surface cleaning, gluing, flocking, drying and curing, and blanking links, with full automated operation: springs are transported to the cleaning station by the feeding system to remove oil stains, then the gluing station evenly applies special adhesive, and then enters the flocking area where fluff is attached by electrostatic adsorption. Finally, the adhesive is cured at the drying station (temperature 80-120℃) to complete flocking. The equipment is suitable for tailgate springs of different specifications, with high flocking uniformity, which can improve the spring's quietness and service life, and is widely used in the mass production of automotive tailgate springs.